Finishing

Vibratory Finisher

Vibratory Finishing, unlike hand polishing, buffing, filing, belting, does not overly depend on the skill of the operator. Instead, it is a mass finishing technique lending itself to batch security and uniformity for the lot. Parts are typically bulk loaded for a long batch process or continuously fed into a vibratory machine for a cellular manufacturing system. Media of various compositions and sizes are used in the bowl. The vibratory action causes the media to act like thousands of small files scrubbing the parts. A compound is used to assist the cleaning/finishing action of the media. The amplitude and frequency of the vibration can be varied to control the finishing of the parts. In a bowl machine the angle between the weights can be varied to control the ratio between the forward motion and the vibratory motion.

The process is commonly used to deburr, burnish, descale, clean, radius, and improve surface finishes. It is ideal for finishing parts prior to painting, plating, heat treating, anodizing, coating and sometimes it is the ideal final finish.

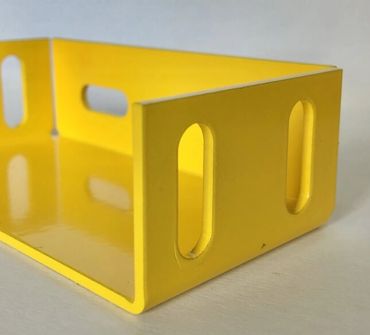

At Schrock, we pay attention to your finishing needs. Our Wheelabrator uses fine blast media to descale, remove surface rust, and welding slag, making it uniform, and improves the coating quality of anti-rust chemicals or powder coating. Interior chamber measures 60" diameter X 59" height. Our Vibratory is an efficient and effective method to debur and eliminate sharp edges on small sheet metal parts.

Time Saver

The process of smoothing the rough edges of a metal object or component. To some, a part is considered deburred when its vertical burr is removed. To others, a part isn’t fully deburred until it has a radius on each edge. This process is a quick and effective way to process multiple parts in a short period of time.

Our Bulk & Shot Blasting Services

Shot blasting is a cleaning, deburring or de-flashing process of parts and materials using a metallic shot propelled at a high velocity.

The process is typically used to remove rust, scale or any other dry surface contaminants from parts, and can also be used to produce uniform cosmetic surfaces on metal products.

STEEL SHOT BLASTING IS AN IDEAL SOLUTION FOR:

- Time-efficient part cleaning

- Descaling

- De-flashing die castings

- Deburring

- Texturing and profiling parts for adhesion

- Texturing for a mechanical function

- Producing a uniform cosmetic finish

- Rust removal

Our primary reasons for blasting:

- Preparation of parts removing oxide and scale prior to welding

- Pre-Prep for powder coating

- Clean uniform finished product for customer products.

Pem Setter/Hardware Insertion

KEY ADVANTAGES OF SELF-CLINCHING FASTENERS

- Provide strong threads or attachment in metal as thin as 0.20 mm / .008″.

- May be installed using any parallel acting squeezing force.

- Provide high pushout and torque-out resistance.

- Do not require special hole preparation, such as chamfering and deburring.

- Reverse side of metal sheet remains flush – no swaged rim protrusion.

- No re-tapping necessary after application.

- Low installed costs.

- Can be installed using automated equipment for high volume applications

Powder Coating

We offer the extreme durability and corrosion protection you expect with our quality powder coating service. Our coating applications are dripless, without runs or application marks, providing you with a remarkably even, thick, dense, and consistent finish. Powder coating enhances efficiency in one application saving money, time, and energy. The biggest advantage is it allows you to customize your color and finish. It is environmentally safe and cost effective. Small quantities or large, we’ll take on anything from small parts to large machine frames—our 16’ batch oven can handle it.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience.